- Satin #4 (Brushed)

- Light Statuary

- Medium Statuary

- Dark Statuary

- Oil Rubbed Bronze (10B)

- Mirror Polished #8

- Antique Brass

- Custom

Brass & Bronze

Brass & Bronze

Stainless Steel

Stainless Steel

- Satin #4 (Brushed)

- Mirror Polished #8

Advanced Architectural Grilleworks

| PATTERN SIZES | OPEN PERCENTAGES |

| 1-5/8″ | 38% Open |

Brass & Bronze

Brass & Bronze

Stainless Steel

Stainless Steel

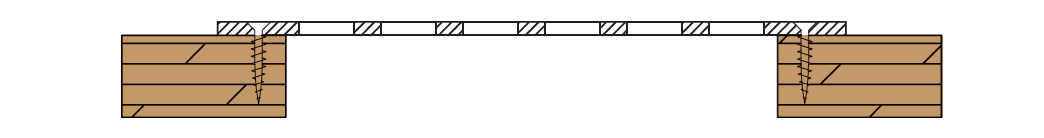

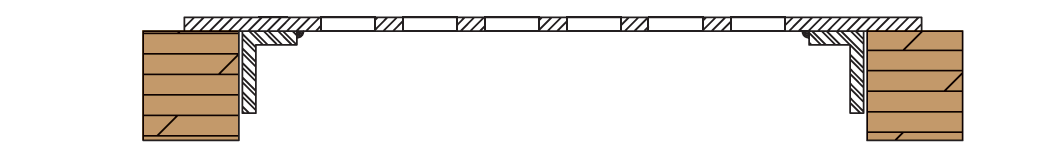

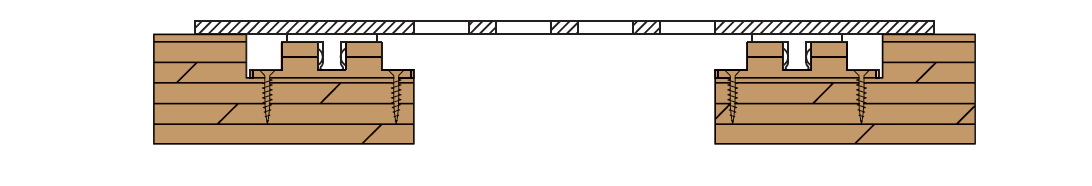

Surface mounted perforated grille with countersunk screw holes.

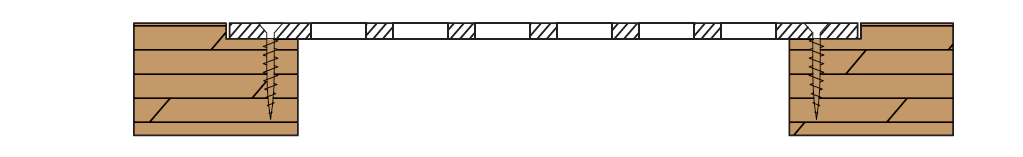

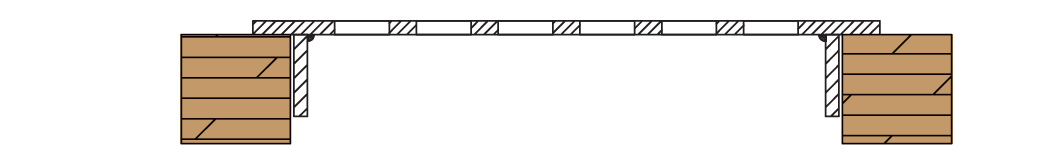

Flush mounted perforated grille with routed opening & countersunk screw holes.

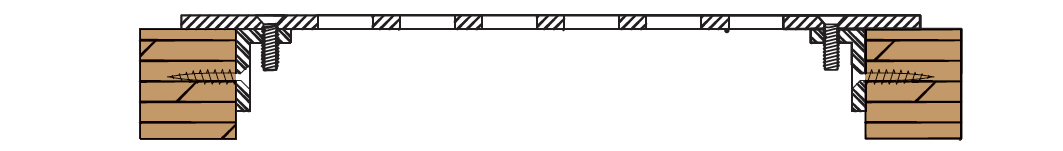

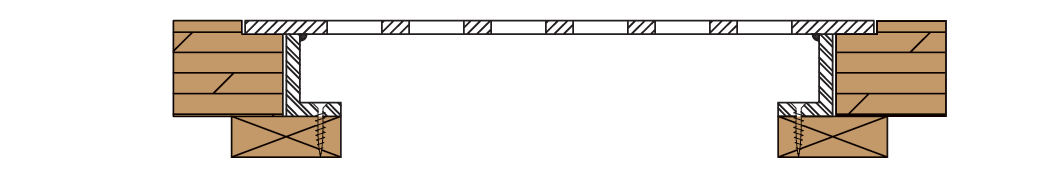

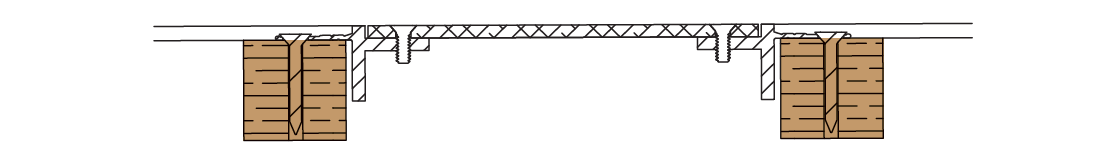

Removable perforated grille with loose angle frame.

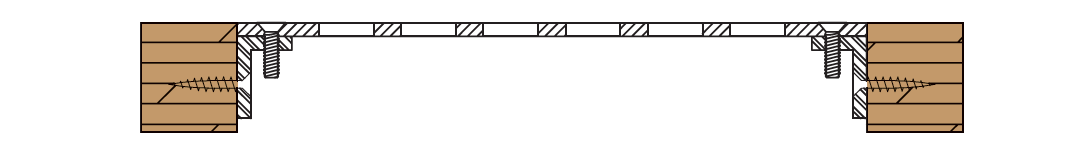

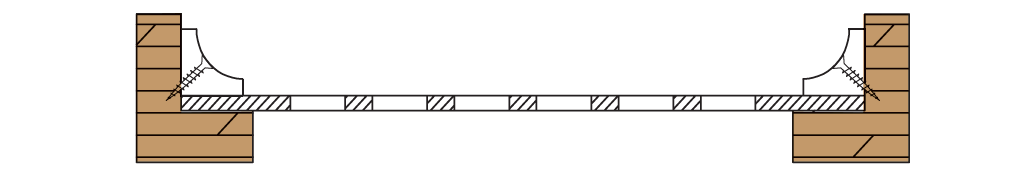

Flush mounted perforated grille with loose angle frame.

Perforated grille with welded stiffener angles for additional support.

Perforated grille with welded stiffener bars for additional support.

Perforated grille installed with wood moulding.

Perforated grille fastened with ball catches.

Perforated grille fastened to plaster J-Bead Frame for wall and ceiling applications.

|

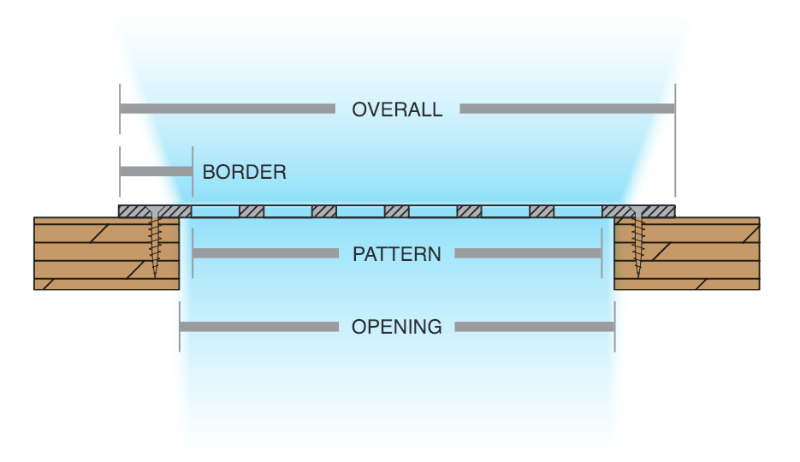

OVERALL |

This is the total length and height of the finished perforated grille — edge to edge. |

|

BORDER |

This is the un-perforated area that surrounds the open area. It creates a frame-like look.** Border size is dependent on overall grille size and your pattern. |

|

PATTERN |

This is the part of the grille panel that contains the perforations, cut-outs or design. |

|

OPENING |

This is the opening in your wall, ceiling, millwork or floor, over which the perforated grille will be installed. |

**Our perforated grille experts can help design appropriate borders to ensure an aesthetically pleasing look.

Please supply the Height and Length dimensions of your opening.